The output and consumption levels of metal pipes in the field of sheet metal processing have significantly increased with the growth of the global manufacturing sector. The majority of consumers have also praised the introduction of metal tube laser cutting machines.

It is widely used in the production of saw blades, electrical components, food machines, medical equipment, hardware, knives, high and low voltage electrical cabinets, advertising signs, mechanical parts, kitchenware, cars, machinery, metal crafts, and other items.

The steel tube laser cutting machine’s superiority is also continually underlined by the development of computer numerical control technology, and it is increasingly taking over as the primary tool for processing sheet metal.

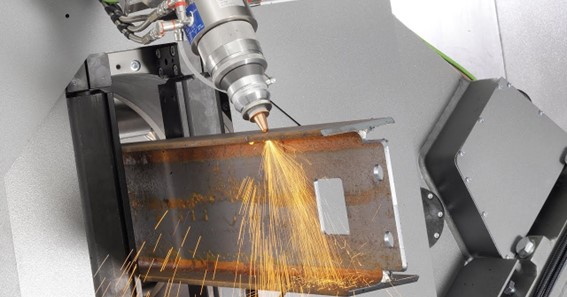

The accuracy of the machinery is substantially increased by using a highly concentrated laser beam to perform laser drilling, slitting, and contour cutting on the surface of the metal pipe.

The advantages of a laser pipe cutting machine is a greater than those of conventional processing techniques.

Click here – Some factors about the comfortable high-waisted bikini bottoms

Benefits of laser cutting metal pipes:

- High precision:

Because manual pipe cutting is still used today, each cut portion is unique. The laser pipe cutting machine uses the same fixture system, and the programming software directly completes the processing design connection, allowing for high precision processing to be done in a single step.

Precision has emerged as one of the key performance indicators for measuring laser cutting in contemporary manufacturing, and laser cutting is currently the more accurate cutting processing method.

Mechanical vibration is decreased because the laser cutting head is not in close contact with the material. The processing precision of the metal tube laser cutting machine is guaranteed by high-precision servo motors, guide rails, and transmission components.

- Quick cutting speed:

Compared to conventional cutting techniques, the laser can cut many meters of pipes in a minute. This means that traditional processing techniques cannot compete with the efficiency of laser processing.

- Flexibility:

The laser pipe cutting machine can process a variety of shapes flexibly, enabling designers to execute intricate designs. In the actual operation, numerous specialty-shaped pipes are cut in addition to the basic round pipe.

The steel tube laser cutting machine can process pipes in a variety of ways, including cutting, beveling, perforating, 45-degree cutting, etc. It can cut square pipes, round pipes, and special-shaped pipes made of metal materials.

- Batch processing:

The usual pipe length is 6 meters, and the conventional processing method necessitates a fixture device. Laser processing, on the other hand, can quickly clamp and position pipes that are several meters long, making batch processing more feasible.

The Senfeng metal pipe laser cutting machine employs an electronic clamping chuck for metal pipes of various sizes and specifications, which can automatically clamp square tubes, round tubes, and special-shaped tubes of various specifications and types, thereby expanding the cutting application range.

How should I pick a laser cutter for metal tubes?

- In accordance with your needs.

You must be clear about the size and other details of the pipe you are processing before buying a laser pipe cutting machine. Then, you must match the appropriate laser pipe cutting machine to your own process needs.

For instance, carbon steel pipe can be up to 5.5 meters long, up to 110 millimeters in diameter, and up to 8 millimeters thick. It merely requires cutting. We are able to supply the SENFENG SF6020T steel tube laser cutting machine, which has a 3000W power output, a chuck diameter of around 220mm, and a 6m length. These details just satisfy your demands, and you can get in touch with us depending on long-term strategies.

- Based on post-sale support.

Large-scale, expensive laser equipment must be installed and trained by qualified specialists. An essential consideration for selecting a pipe cutting machine is the after-sales service. With a skilled workforce in research and development, production, sales, and after-sales, Senfeng Laser can offer services and support to clients worldwide. Free on-site installation training is what we offer.

Application of laser tube cutting technology

Domestic water, sewage, industrial water, and petroleum are typically transported by metal pipes, particularly stainless-steel pipes. Because of this, the laser pipe cutting machine may be used for heating, power, oil, sewage treatment, water supply and drainage, etc.

Additionally, laser cutting machines play a significant part in the fabrication of metal pipes in the construction, sports and fitness, medical, automobile, and equipment industries.

Click here – What are Bearbricks? A complete guide